Chopping board - one of the main attributes of the kitchen. Classic kitchen products are used for cutting vegetables, meat and fish. Some models are only for serving food or serving the table. A great professional used by chefs in restaurants.

Features and types

Professional cutting boards produce from a special raw material, which is a natural, pure material and has high strength. The wood extruded fiber used to make these products ensures safe use and long service life.

The surface is usually saturated with oil or wax. This prevents fluid from entering the cutting board fibers.

Wax and oil push water and juice products to the surface.

Professional cutting boards are used when cutting and chopping products, cutting fish, cutting bread, cheese and sausages. The surface of such products is made of tough, dense wood, therefore on professional boards it is convenient to beat off meat.

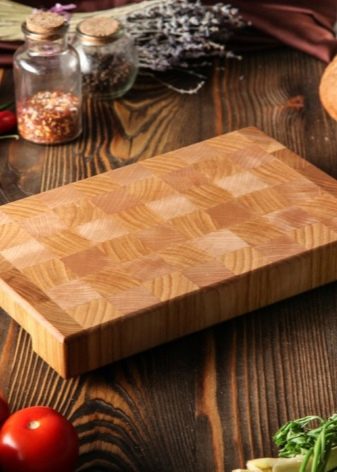

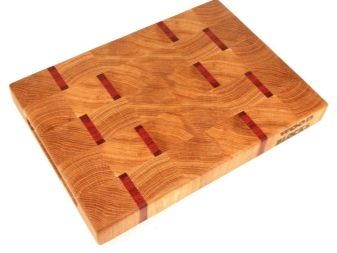

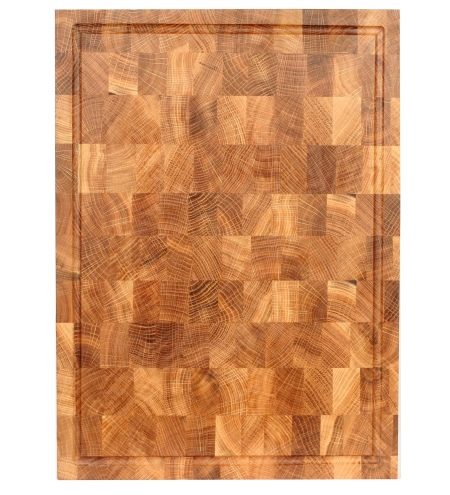

End boards

Of the professional finishing products worth noting end board. In conventional wood models, wood fibers are arranged parallel to the cutting surface. In the end product wood fibers are located strictly perpendicular to the surface.

When processing products and contact of the blade with the cutting surface, the wood fibers move from side to side. After that, the wood fibers return to their original position. During the contact of the knife with the surface of the usual cutting surface of the blade cut the fibers of wood.

You may even notice that the surface of conventional wood chopping boards eventually becomes rugged. This means that pieces of wood from time to time get into the food and stomach. When cutting products on the end product, the surface of the product is not deformed, and the knives remain sharp longer and do not require frequent sharpening.

The end model also has antimicrobial properties. After contact with the fiber blade, the surfaces “close in”, and the oily surface of the end-plate protects the wooden fibers from penetration of harmful bacteria and compounds.

Materials

Professional finishing products are made mainly from high-quality wood. It may be oak of the highest quality, beech, bamboo, as well as glass and plastic.

Wood cutting boards used in ancient times. And for modern man, such products are more familiar. When using wooden boards, the blades retain their properties longer. Products made from natural raw materials, so they can be safely called more hygienic than the boards of another material.

Products from bamboo quite practical, have a long service life and are resistant to damage. They do not absorb liquids and odors, the tip of the knives is less deformed. Disadvantages include high cost and size. Most often bamboo products are of small and medium sizes.

Products from glass more designed for serving dishes and serving the table. During production, a variety of patterns and patterns are applied to the glass surface. This product looks aesthetically pleasing, but not practical to use. Upon contact with the glass, the knives lose their properties, and when cutting food, the surface produces an unpleasant creak. The disadvantages include the fact that Do not use ceramic knives on the glass board.

In the manufacture of plastic used plastic of various thickness. Boards made of thin plastic are quite cheap, do not absorb odors and have a long service life. Colored plastic boards can be used for washing in the dishwasher. Of the minuses worth noting instability to high temperatures and sliding on the surface of the table. Do not use the product as a product feed. The surface bends by weight.

Dense plastic is used in the manufacture of higher-quality professional products for cooks. Thick plastic includes polypropylene, polyethylene, vinyl plastic.

Products from dense plastic are not deformed, resistant to high temperatures, do not blunt the blades of knives, do not absorb odors and water, they wash well and are almost eternal. The only drawback is the weight of the products. Thick plastic boards are quite heavy.

Silicone make special mats for cutting vegetables. Figuratively they are called cutting boards.

They are easy to wash, do not fidge around the table, do not blunt the knives. These boards save space. They can simply roll up into a roll.

Manufacturers rating

On the Russian market, professional chopping models are represented by several manufacturers at once.

- Shteiger. This Austrian company produces cutting boards from high-quality wood throughout Europe. The cutting boards of the Austrian manufacturer for a long time retain their original appearance, endowed with protective properties against bacteria, do not absorb food juices and odors.

- Pure chess make models of oak. The use of products from this company prevents rapid wear of the knife blade. The surface is impregnated with oil, so that water and odors do not penetrate into the wood fiber.

- Humpty dumpty - another manufacturer of professional cutting surfaces. In the manufacture of used oak wood.

- Pure oak. Material for production - oak of the highest quality. The model of such raw materials has many properties that will help in the preparation and processing of products. The only negative is the high cost of products.

Proper care

An ordinary product can simply be washed with a small amount of detergent or under hot running water. For professional cutting boards need special care.

Some nuances to remember when using professional products:

- Do not put the board in the oven or microwave;

- do not store the product in the vicinity of cooking stoves or heating;

- after washing, wipe and dry thoroughly;

- can not be washed in the dishwasher.

From time to time, the cutting surface should also be wiped with mineral oil. In this case, you can use flaxseed or sunflower oil.

Processing can be carried out once in 2 months.

For processing it is necessary to take a piece of cotton cloth soaked in oil. Circular movements of oil rubbed into the surface of the cutting board. After this, the product should be left alone for 8 hours. The board will absorb the right amount of oil. When oil remains on the surface, wipe the product with a clean cloth.

The pros and cons of chopping boards from different materials are listed in the video below.