Any items that have a cutting edge, even being made of expensive alloys, become dull with time. Because of this, such equipment becomes difficult to perform the actions for which it is intended. To fix the problem, you should purchase a special sharpener. Depending on the requirements of the owner, the type of steel from which the knife is made, it will be necessary to give preference to different sharpeners. How to choose them, the principle of operation of the tool and the rating of the best manufacturers of kitchen sharpeners, you will learn from our article.

What it is?

Knife sharpener is a solid cloth made of abrasive material that can grind the surface layer of soft metal. Sharpeners are presented in various variations, such as manual, mechanical, electrical and so on. There is also a grinding stone, which, according to its characteristics, differs from the kitchen sharpener, which is familiar to us all.

All types of sharpening tools one principle of use - the outer edge of the blade of the knife is superimposed on the abrasive side of the sharpener at an angle or flat (depending on the type of device) and the forward and backward sharpening of the blade occurs.

These tools are suitable not only to give sharpness to the blade of kitchen knives, but they can also sharpen scissors, sickles and other equipment with a cutting edge.

The abrasive coating can also be used to remove cracks and roughness from the surface of steel objects, smooth out small curvatures of the blade, and polish the surface of the tool. If you choose the wrong type of sharpener, or rather its coating, the kitchen fixture may become dull during sharpening or, on the contrary, the surface of the sharpener itself will be damaged.

Advantages and disadvantages

Each type of sharpener has its pros and cons. The disadvantages of electric sharpeners applies engine braking with a strong pressure blade on the machine, that may affect the quality of sharpening tools. Pros - the speed and ease of sharpening.

Manual sharpeners require more time and effort to sharpen the tool, which for some people may be a minus, but such a sharpener will serve faithfully for decades, as well as does not require electricity. The same applies mechanical grinding machines. However, its cumbersome size, as well as the presence of dexterity in working with the device, do not make this tool massively used. But these sharpeners are suitable for sharpening a variety of objects with a cutting edge: braids, sickles, scissors and so on.

Sharpening bar It is convenient to use, but this item is classified as traumatic, since there is no handle or protective frame on the bar. Sharpening speed average, quality. The grinding bar has a long service life. Sharpeners with metal rings (roller) easy to use, transport and store. But the quality of sharpening is almost average. This tool is only suitable for household scissors and knives. For high-quality sharpening kitchen tools it is recommended to use musat. It does not require proficiency, is easy to use and allows you to achieve maximum sharpness of the blade of a kitchen knife, as well as its convenient to store.

Kinds

Tools for sharpening can be divided into several segments according to the functional feature.

- Standard sharpeners. Inventory of a simple form, abrasive material is placed in the body of the object at an angle from two or one side of the sharpener. These may be the following options:

- desktop vacuum sharpener on the suction cup, which allows the tool does not slide off the table and frees the hand;

- sharpener, brass knuckles or pocket, which is worn on the hand;

- roller, which is a metal ring embedded in a plastic or metal case;

- “Fish” - the object is made in the shape of a fish, where the fish’s carcass is a handle to hold the sharpener, and in the tail of the device there are sharpening rings or a stone;

- a circular sharpener that looks like a yo-yo toy, where a grinding blade is placed in the middle of the design.

- Knife Blade Products. These are usually mechanical or automatic electronic sharpeners. An object with a swivel mechanism allows you to securely fix a knife or other object in the sliding holders of the grinding machine, safely sharpening inventory. Sharpeners with an adjustable angle of sharpening or with adjustable degrees are equipped with a special button that allows you to set the desired angle at which the abrasive material will be placed in relation to the cutting edge of the tool. This feature helps to quickly and easily sharpen knives at home.

- Sharpeners with a free movement of the knife when fixing a grinding stone or coating. These fixtures of stationary type are most often used in repair shops. Table sharpener is a monolithic structure, on which in the form of a tape abrasive material is stretched. Belt sharpeners are always electric. The motor spins the canvas at a predetermined speed, sharpening the object occurs in free movement.

- Tools for sharpening without fixing. These are any types of sharpeners that do not need to be placed on the surface. These include musat, foldable, bar and others. These devices are versatile to use, easy to transport. Inventory with a freely variable grinding angle has a great advantage than sharpeners with fixed stones, but they require skill.

Mechanism of action

There are several varieties depending on the mechanism of action.

- Electric sharpener. This is a cumbersome tool, used mainly in places of public catering, in production. The device and the size of the machine allow for a short time to properly sharpen a large batch of sharp tools. Today you can find models designed for home use.

- Grinder. It can be a mechanical or automatic device. The device is a footrest for accelerating the drive or a stand with a motor. Directly to her fixed clamp, flywheel. When the machine is connected to the mains, the motor accelerates the sharpening disk at a given speed. In the mechanical type, the movement of the disk is driven by a foot mechanism. The surface of the sharpener is made of stone with a dusting of diamond grit. The kitchen tool is applied to the disc plane at an angle, the blade of the knife is held by hand. For sharpening the blade will be enough for a few seconds.

To use the grinding machine, you will need a knack, as well as compliance with safety regulations.

These machines are versatile, allow you to put in order the garden and other equipment. Automatic sharpeners are smaller than mechanical sharpeners and are used primarily in the home. It is safer, it can be used to sharpen knives made of ceramics.

- Manual sharpeners they are an abrasive block fixed on a handle or just a grinding block. The principle of their work is simple. These devices do not require specific skills from a person.

Musat

The tool is made of a metal rod with a scar and handle. It has a light weight, ease of use, compact size.Sharpening inventory is carried out as follows: the edge of the blade of the knife is located relative to the sharpener rod at an angle of about 30 degrees, turning movements of the working surface of the knife. The main thing - the movement should be in the same direction, for example, the hand moves only forward. Obtachku produce from two sides.

This tool allows you to quickly sharpen knives, but the quality of the facing will not be very sharp, and the effect does not last long. Musat allows a kitchen or other inventory to maintain its working condition for several weeks.

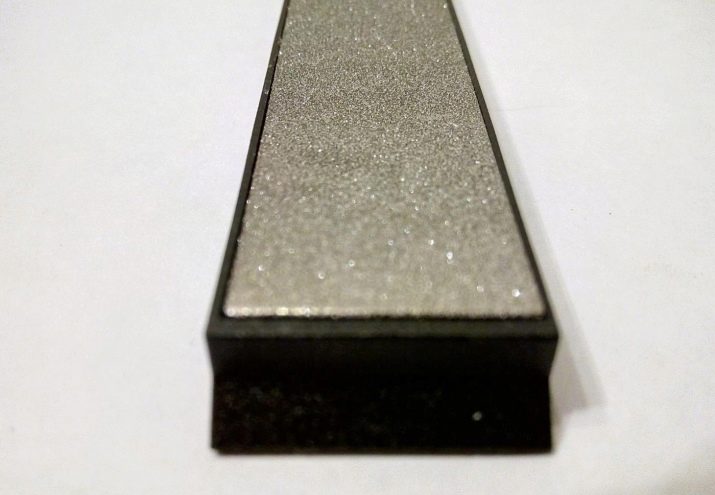

Bar

The grindstone is a simple grindstone with an abrasive dusting in the form of diamond grit or silicon. Before use, it should be wetted, like a knife. The tool is applied to the bar at an angle, then cutting of the cutting edge is performed. On one side is enough eight movements. To properly sharpen the knife, you need skill and skill.

The grinding bar is a traumatic device, be careful when handling inventory.

Manufacturing material

Consider the types of spraying used for grinding devices, as well as the abrasive grit.

Coarse-grained

This abrasive is used for blunt knives. A strong impact can give the instrument the same sharpness, remove serrations, chips.

For systematic sharpening of knives, it is not suitable, for this it is better to use softer abrasives.

Sharpeners with a coarse abrasive are produced in the form of manual, electrical and mechanical devices.

Medium grained

Most often, this option is made of diamond, silicon chips. It is considered the most versatile coating. The device with a medium-grained abrasive copes with the removal of small irregularities on the cutting edge, while giving the blade sufficient sharpness. Diamond coating is not able to spoil the aesthetic appearance of the inventory.

It is suitable for turning knives with a blade half a centimeter wide, no more. Too wide edge can ruin the sharpener.

Fine grain

For home use fine-grained abrasive is not suitable. Sharpeners with this abrasive are used for grinding and polishing working tools, sharpening nail accessories. Fine-grained abrasive is available as an additional nozzle for sharpeners. Soft coated bars can sharpen ceramic tools, but the quality of sharpening will be average. For better sharpening it is better to use sharpeners with a diamond coating.

How to choose?

The choice of sharpener depends on the following factors:

- where the sharpener will be applied;

- type of tool to be sharpened;

- mastering skill grinding device.

It is worth noting that musat is not considered a sharpener. This item serves exclusively to correct the blade and is used only at the final stage of sharpening.

Musat allows the kitchen knife to remain sharp longer and increases the life of the inventory. If the cutting edge is slightly dulled, then the musat can be used. In other cases, apply sharpeners with properly selected abrasive material. As a rule, musat is widely used by chefs.

If sharpening tools will be made only at home, then you can buy the most simple and versatile sharpeners, for example, products with metal discs or with a coarse-grained coating. Such inventory costs about 400 rubles. Objects with natural or synthetic stone (electrical, mechanical, manual types) will cost an average of 1500 rubles.

All products intended for polishing knives, or sharpeners of complex design with a wide profile of work will be about 5-10 thousand rubles. Professional tools, grinding stations with high-quality abrasives are the most expensive. The price on the market starts from 10 thousand rubles.

Top Rated

The table shows the top of the best foreign products.

Model | Material | Sharpening angle | Product price in rubles |

Stayer Master 47511 | ceramics | 100 | |

Mallony KS-3 | steel or ceramics | 270 | |

KitchenIQ 50044 | ceramics or carbide | 20 | 650 |

GiPFEL 2919 | ceramics + diamond plating | 1000 | |

Rondell RD-982 | ceramics | 12-25 | 1200 |

GiPFEL 2902 BOND | ceramics + diamond coating | 1380 | |

Victorinox 7.8715 | carbide | 20 | 1600 |

Samura KSS-3000 / Y | synthetic stone | 3500 | |

Arcos Afiladores 6101 | stainless steel | 20 | 15200 |

Samurai shark | carbide | 450 |

The table below provides an overview of Russian devices.

Model | Material | Sharpening angle | Product price in rubles |

"Profile K-02" | size range from 5 natural stones | 0-40 | 19350 |

"Warehouse" | diamond bars | 0-40 | 7600 |

"Profile K-01" | diamond plates | up to 40 | 14900 |

Adaptations of the Russian manufacturer are designed for professional use. Manual and simple products for sharpening knives are best to choose among the products of Switzerland, America, Spain.

Japanese technique is best suited for knives made in Asian style - as a rule, the alloy is thicker, the cutting edge is wider, and a certain degree is required for sharpening, so evenly set metal discs in the grinding device will not work. The same applies to Chinese products. These products differ in reasonable price and a qualitative covering.

For large knives or items of irregular shape, stationary stations are selected with angle adjustment, clamping.

Swiss devices are notable for ease of use, durability, high-quality abrasive materials. Particularly popular products of the company Victorinox. American brand sharpeners Chef's Choice are versatile. Each machine is equipped with three grinding holes, which differ in the angle of sharpening, abrasive coating. That is, you, using only one device, can put in order knives made of different materials, for example, steel, ceramics, as well as polish them, carry out fine-tuning.

Reviews

Among the Russian devices can be identified conventional grinding diamond bars. Products are delivered in cases, the price of the device varies in the region of 450-750 rubles. Instructions for use are attached to each bar. The basis of the product is made of aluminum. The consumption of material is minimal. The owners note the ease of use of sharpeners, the ability to edit and sharpen kitchen and hunting knives, razors. They do not leave scratches on the surface of the tool.

Roller-type manual sharpeners have medium popularity because of the quality of sharpening a knife. These devices do not work with Damascus, high carbon and forged steel. They are able to leave damage to the metal or, conversely, make the blade more dull.

Roller products are suitable only for simple kitchen knives.

The product “fish” buyers noted as the worst. It is inconvenient and dangerous to use the device, since according to the instructions, it is necessary to make the grinding not with the tool, but with the sharpener itself.

According to the manufacturer’s advice, the knives should be held on the edge with a blade to oneself. The material of which the sharpener is made quickly deforms, the quality of sharpening the cutting edge is low. The product quickly becomes unusable.

Sharpeners Japanese manufacturers are marked by positive reviews. These devices can be put in order scissors, knives, as well as they are suitable for serrated blades. Product company Samurai shark made of high quality plastic, abrasive material - tungsten-carbide. The device is easy to use, the speed of sharpening is fast, the quality is high, the tool does not require much storage space.

In the following review you will get acquainted with some types of pocket sharpeners for knives and the identified features that can lead to very negative consequences.