Metal is actively used in the manufacture of kitchen utensils, dishes. One of the most popular is stainless steel. It stands out for its positive features in terms of quality and appearance, in the light of which stainless steel utensils can be found in almost every kitchen.

A bit of history

The stainless steel has been known to man since the days of ancient Egypt and India, fragments of kitchen utensils from this metal date back 1000 years BC. Today, the inventor of stainless steel in the modern sense of the composition is called the scientist G. Brearli. Alloys, which today are used for the production of kettles, pots and other kitchen utensils, patented in the late XIX century.

The peak of its demand for stainless steel utensils reached only at the beginning of the XX century. The monopolists among the manufacturers at the very beginning were Asian companies that manufactured products at an affordable market value. Quality did not always meet the expectations of consumers, so some brands left the market forever, but most manufacturers sell their metal products for cooking to this day. Among them stands the elite dishes, inexpensive products, low cost tanks of the army and marching type.

Not so long ago, stainless steel utensils made in Turkey appeared on the counters of supermarkets, which proved to be positive in terms of design and quality.

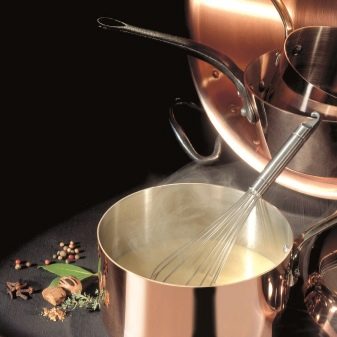

The most famous manufacturer is the French company De Buyer.However, earlier she specialized in creating only elite steel kitchenware. Among European brands also stands out Italian brand Paderno. Domestic manufacturers entered the market not so long ago, but the products of Russian companies today comply with established international quality standards, and therefore are successfully sold in the Russian Federation and abroad.

Advantages and disadvantages

Modern stainless steel cooking products have positive and negative properties. The advantages of kitchen utensils made of stainless steel must include a number of nuances.

- The main advantage of such dishes - both in the set and separately - is the external attractiveness. Complementing the charm of shiny surfaces is the presence of glass covers, which are most often sold in a set of dishes.

- Metal stands out for its large operational resource, therefore, with proper maintenance of kitchenware, it will be enough for 10 or more years.

- Steel is resistant to mechanical damage, unlike glass or ceramics will not crack if accidentally dropped.

- Hygiene is an important aspect for containers in which food will be cooked regularly. The metal structure is distinguished by the absence of pores, therefore, it will be much easier to clean containers from various kinds of contamination in comparison with porous raw materials.

- Steel is compatible with all types of hobs and hobs, including induction models.

- Stainless steel is not harmful to human health, so you can safely prepare any food from any food in it, in addition, food can be stored in containers after cooking.

However, the metal is not without some minuses. The disadvantages of raw materials for the manufacture of dishes for the kitchen need to include several factors.

- Outside the metal will remain traces of any contact that may adversely affect the appearance of utensils.

- Due to the fact that the temperature inside the tanks is unevenly distributed, there is a risk of burning products. But in pots and pans with a thick bottom this happens very rarely.

- Steel is not resistant to sudden changes in temperature. In such situations, defects may appear on it.

- As a rule, dishes of good quality from such an alloy stand out for their high cost.

Varieties

Today, under the common name "stainless steel" hides several types of metal alloys, which are applicable for the production of containers for the kitchen. Most often manufacturers use various alloyed alloys.

- 18/10 - A popular raw material that is used for the manufacture of professional and elite dishes. Today, austenitic alloy is claimed by Russian and foreign manufacturers.

- 201 - A similar alloy is also called medical or surgical. But despite this definition, the metal is most often used for the production of dishes of the budget price category. Such a reduction in the cost of steel products is due to a composition in which most of the nickel will be replaced by manganese.

You can meet this alloy in cutlery, as well as other containers that are not intended for the heat treatment of food on the stove, in the oven or in the microwave oven.

- 430 - ferritic alloy, not having in its composition nickel. Such a metal is in demand for the manufacture of multi-layered "sandwich" at the bottom of kitchen containers.

- 420 - a safe alloy, which stands out among the other varieties for its high strength. Most often from this raw material make forks, spoons, knives.

The classification of stainless steel cookware can also be made based on the method of its release. Raw materials from the budget category produced by stamping, expensive utensils made by casting.

Manufacturers Overview

Today, metal utensils are presented in supermarkets in a large variety, which allows each hostess or cook to choose the option that is most suitable for cost and performance. Among the manufacturers of steel kitchen utensils, it is necessary to distinguish several manufacturers.

A bountiful harvest

Domestic brand that has established itself from the positive side in the light of the high quality of the dishes. It is especially appreciated by lovers of the canning process. The range includes pots and other dishes of different capacities with convenient lids that withstand prolonged exposure to high temperatures.

Fissman

The steel ware from Germany which is allocated with the high quality standards, corrosion-resistant properties. Products are durable, which allows them to operate for quite some time. The range is presented product line of elite class, when creating which the manufacturer emphasized on the appearance, in addition, The trade brand offers products of an average price segment.

Berghoff

Steel dishes are presented in a large variety. Cooking containers are made with a heat-accumulating bottom, which will allow food to heat up faster, in addition, you can keep the dish longer in such dishes, keeping it warm.

Tefal

A popular brand that offers consumers a large selection of various carbon or galvanized steel products with a high level of quality. The products of this manufacturer are used by many professional chefs, cooking pots are equipped with capsular bottom, consisting of several layers of metal, which has a positive effect on the cooking process.

Kaiserhoff

Another German manufacturer that sells various kitchen utensils, including stainless steel. The products stand out for their attractive design, for ease of use, the containers have a small scale on their walls, allowing you to adjust the volume of fluid inside. For the production of utensils used high quality metal.

Calve

Cookware of this brand is different from the rest of the range of its appearance, in addition, all steel containers used for cooking, have a non-stick coating, which eliminates the appearance of residues of burnt food on the walls and bottom.

Tanks are considered universal, therefore, compatible with all types of hobs, in addition, they can be used in ovens.

How to choose?

The harm and benefits from the operation of steel utensils are caused primarily by its quality, so the choice of containers for cooking should be approached with great responsibility. In order not to be mistaken when buying stainless steel products, It is recommended to pay attention to several features of products.

- It is best to initially buy dishes of universal purpose, which can later be used on any type of stove, in ovens, microwave ovens. Such products should contain 430 markings on the outside of the bottom. It is this version of the alloy that will allow the tanks to be operated in any variants.

- Quality dishes, if it assumes the presence of a lid, should not contain gaps between its walls and the lid itself. This will ensure a uniform temperature distribution inside the dishes, in addition, excess liquid will not boil away from the cracks on the stove.

- The optimum thickness of the bottom of steel utensils should be a value of 3 mm.

- For pots, the optimal wall thickness will be at least 0.5 mm; as for frying pans, for them this parameter starts at 1 mm.

Terms of use

There are several general guidelines for the safe operation of stainless steel cookware. compliance with which will significantly extend their operational life.

- Metal containers must not be set on fire empty.

- Using pots, pans or other containers on gas burners, it is necessary to set the level of the flame under the container so that the flame does not extend beyond its limits.

- It is not recommended to heat stainless steel dishes with too high temperatures. Therefore, dishes are best cooked over low heat.

- During the mixing of food can not use metal devices. Spoons, skimmers and other products should be made of silicone or plastic. Use of wooden products is allowed.

Care features

Stainless steel utensils will last longer if carefully take care of it.

- In order to make it easier to care for stainless steel containers, it is recommended to salt them during cooking only after boiling the liquid or, in general, at the end of cooking. Thus, it will be possible to avoid the occurrence of scale on the walls.

- If the dishes are operated with hard tap water, the white residue from the walls will be removed by boiling the containers in water with the addition of table vinegar. And also get rid of stains on the surface will be using citric acid - it will need to clean the place with neoplasms.

- Do not clean hot pans, bowls or pots. Without losses, it will be possible to wash the containers only after they have cooled down; you can additionally soak them in warm water with or without chemicals.

- To clean the dishes from carbon deposits, scale or plaque at home, it is better to regularly care for stainless steel products, avoiding the use of abrasive substances and sponges with a hard surface.

- During the operation of dishes it is better to take care of her manually, avoiding the use of a dishwasher. If there is a recommendation to wash in the instructions for the dishes by machine, before such a treatment you should soak the container for a while in a soap solution.

- After washing the container, it is best to wipe it dry additionally with a waffle towel.If you leave products from steel to dry naturally, on the surface may remain drips and stains. To finish the shine on the walls, it is recommended to wipe it with a dotted, non-circular motion.

- If the detergent composition for steel surfaces was chosen incorrectly, scratches could appear on the walls and bottom. In this case, it is necessary to replace the detergent composition with a more gentle and soft substance.

How to choose stainless steel dishes, see the following video.