Today in stores you can often find things from the footer. This fabric is becoming increasingly popular. The principle of its manufacture is lined weaving, in which back threads are additionally tied into the main thread. Today the footer is actively used in the light industry for tailoring.

Features

Things made of footer, differ not only convenience, but also comfort for the body. This is due to the fact that the footer is nothing more than a pleasant to the touch cotton knitwear. It is smooth in texture on the front side, and on the back - soft and fuzzy. Unlike fleece, which consists entirely of polyester, the base of the footer is usually 100% cotton. That is, fleece is actually synthetic wool, and footer is cotton knitwear. Due to the natural composition and good heat retention, the footer is warmer than fleece. Therefore, when choosing a warm fabric, it is better to give preference to the footer.

Synthetic fibers are also added to various types of this material. They make the fabric more warm, durable, wear-resistant. However, their percentage in the material is small. It must be remembered that the quality fabric is at least 90% cotton. The density of the fabric can be in the range of 170-350 grams per meter, depending on what percentage of synthetic raw materials contain material. However, in any case, the footer, compared with cotton, is designed for a longer period of operation.

Basically, the following raw materials are added to the material:

- wool fiber - it makes the footer warmer, this fabric is well suited for sewing outerwear;

- polyester or lycra - footer with the addition of these threads is more elegant and durable, it is better to sew casual clothes from this material.

Production

This fabric is made on a loom using two types of threads - a smooth warp and a weakly twisted footer. A regular thread forms the basis of the fabric from the front side, and the thread from the footer is used to fabricate the inside of the fabric with a pile using a looped broach. That is why this material is also called footer-loop or looped footer. The fabric manufacturing process consists of two stages - first, looping the main fabric with looped broaches, and then adding loose lining yarns.

Varieties

The fabric is available in several varieties depending on how many threads were used in the manufacture of the material.

- Single footer - is the thinnest material and 100% cotton. It is usually used for sewing diapers, as well as sliders, overalls and other clothing for newborns. Due to the fact that the fabric retains heat well and is soft, using it does not form wrinkles that can give the baby discomfort. Footer, which is used for children's things, can be printed, that is, contain drawings and combinations of different colors.

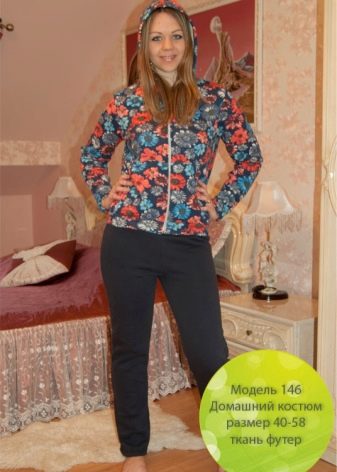

- Footer-dvunitka - this fabric differs in average density. Often made from mixed raw materials with the addition of lycra or polyester. Synthetic fibers give the fabric elasticity and dimensional stability. From this fabric sew children's and home clothes, tracksuits.

- Three-thread footer - for the manufacture of such a fabric, additions in the form of wool or synthetic fiber are also used. Due to this three-filament footer is the most dense and has a thick pile.That is why this material is indispensable in the production of outerwear, turtlenecks, sweatshirts, warm home wear.

- Footer with fleece - thermal underwear and children's overalls, as a rule, are made from this fabric. In things from this material, the skin breathes due to a dense pile, which perfectly retains heat inside. Gray melange is the most popular type of such footer. It is a material consisting of cotton and synthetic fiber in the proportion of 80/20 percent, respectively. It is used for the production of sports suits and elements of outerwear, since this fabric is non-marking.

Additionally, the types of footer emit depending on the method of its manufacture. The difference of these types of fabric is their durability.

Basic types:

- singing;

- boxing ring;

- openen.

Cheaper products sew from material opennd. Such things look worse, much less durable and cheaper in cost. Also, many manufacturers seek to reduce the cost of fabric through the use of cheap dyes and artificial fleece. Such products quickly lose their presentation after the first wash - the color fades, and the pile in the form of a glued cotton layer crumbles. No useful properties of things made of artificial materials are not.

How to care for products?

Since the footer is a natural fabric, it needs special care. Especially important is the observance of temperature during washing. Otherwise, the product from the footer may be deformed or lose its properties. In this regard, it is better to buy things from the footer a size larger. If the product shrinks, it can still be worn despite this. In order for the product to serve for a long time, you need to follow the following rules of care.

- Temperature wash. Machine wash the footer should be carried out at a temperature not exceeding 30 °. Raising the temperature to 50 ° is acceptable, if the fabric is very dense - more than 300 grams per meter.

- Hand wash is also allowed. But to boil the product from the footer is not recommended, as the fabric may be damaged.

- Before starting the product in the washing machine, it must be unscrewed seamy side inside. This will protect the fleece part from damage from interaction with hard objects - buttons, clasps, etc.

- Care for color and white things. White footer can be washed with a simple powder, but black or colored material requires special care in the form of delicate gels or powders. This will help to keep the color and good appearance of the thing.

- Spinning Products from the footer can be subjected to spin in a washing machine, even at high speeds. The material will not suffer from this.

- Drying. When drying, it is important to avoid UV rays on the fabric. For this, things should be dried in the shade in a natural way.

- Ironing. If the fabric is high density, then you can use the “cotton” ironing mode. If the density of the material is less than 200 grams per meter, then it would be better to choose the delicate mode. To iron the product from the wrong side and not damage the nap, it is better to select the "silk" mode.

Advantages and disadvantages

Products from a footer gradually become very popular in the light and textile industry. High-quality material, simple maintenance and low price make them attractive to buyers. Unambiguous advantages of the fabric consumers call the following characteristics.

- Naturalness and environmental friendliness. The natural composition of the fabric makes it applicable for children's clothing. In addition, the material is hypoallergenic and does not cause irritation on the skin.

- Air exchange The fabric circulates oxygen and retains heat well inside. Due to this, there is no feeling of stuffiness in footer products.

- Hygroscopicity. The footer absorbs moisture well. It is logical that clothes for sports and outdoor activities are sewn from the footer.

- Elasticity. The fabric stretches well, does not constrain movements.In the process of wearing the product does not stretch and does not lose its original shape.

- Wear resistance. The material is durable and resistant to mechanical damage. In addition, the pile of the material withstands repeated washings well. The fabric does not form the pellets and other spoiling kind of bumps.

- Ease of care. To preserve the marketable appearance of products from the footer does not require compliance with too complex rules of care.

- Cost Products from a footer are available at the price to any buyer.

In addition, the fabric is simple enough for self-processing at home. That is, to sew clothes from the footer on their own, no special tools and tools are required. It will be enough to use a needle to work with knitwear. The disadvantages of the footer include ultraviolet intolerance and high temperatures. Under the influence of direct sunlight, the fabric is destroyed, therefore after washing it is recommended to dry in a dark place. If the washing mode is not observed (temperature is above 30 °), the fabric may be deformed. In addition, it is also better to dry products away from batteries or heaters.

At observance of all these rules the product from a footer will serve long and will not lose the trade dress even at long operation.

How to sew footer clothing with a fleece, see the next video.