Superhard alloys based on metal and ceramics were created by scientists of the USSR Academy of Sciences more than fifty years ago for the manufacture of gas turbine blades, drilling tools crowns, rib prostheses, individual segments of the spine, jaws, bones of the musculoskeletal system, tools for processing heavy-duty metals, dentures and some other products.

Features of ceramic knives

The composition of the new superhard alloys included metals (zirconium, cobalt, vanadium, aluminum, chromium, nickel, molybdenum, titanium) and ceramics components (silicon carbide and aluminum silicate, boron). An alloy of non-miscible components (molten metal and silicates) was obtained by sintering a finely dispersed zirconium powder, silicate sand and dopants in an atmosphere of pure oxygen at a temperature of more than + 1500 ° C and an overpressure of more than 200 atmospheres in a diamond tube.

Today, steel cutting tableware, rusting and requiring constant care, has been replaced by ceramic with a blade made of pressed amorphous zirconium carbide or zirconium dioxide. Briefly consider their advantages and disadvantages.

Ceramic knives have the following advantages:

- sharpness - ideally sharpened blade surface allows you to quickly and easily cut fresh meat and fish, to carve bird carcasses; it is especially convenient to use for cooking a large number of dishes in a short time in cafes, canteens, restaurants;

- zirconia knife does not need to sharpen daily;

- a thin film of zirconium oxide on the blade prevents products from interacting with the metal;

- food residue and grease do not stick to the smooth surface of the cutting edge;

- a sharp knife does not require the use of excess effort, reduces the likelihood of cuts on the fingers;

- Metal-ceramic dagger attractive look can be used for cutting meat, cake, pudding, pineapple, watermelon and other products at the holiday table;

- Zirconia knife does not lose sharpness when exposed to high temperature;

- from the remnants of food the knife is easily washed with soapy water

This product has the following disadvantages:

- a brittle blade - when falling from a great height on a tile or on a concrete, the blade of a blade can crack;

- sharpening the metal-ceramic knife is possible only on a diamond coated bar;

- a short blade with a length of not more than 18 cm is very inconvenient to cut a large watermelon or pineapple;

- after cutting containing stained fruits and roots (beetroot, dill), the blade must be washed with water;

- metal-ceramic knife can not cut frozen meat and chop bones;

- Ceramic blade can not cut products on the tabletop of stone, polycarbonate or doped plastic.

Important! The high hardness of the blade of metal-ceramic when sharpening from the main advantage turns into a major drawback. Sharpen such a kitchen tool can only be on the bar with a diamond coating.

One-sided or double-sided tip?

A minor inconvenience when using a knife with a ceramic zirconium blade sharpened on one side is to shift (slide) towards the flat face when cutting fluffy soft products (pudding, mousse, jelly, jelly, margarine, butter, cake, and others).The ceramic knife of the Japanese manufacturer of the classical form has a flat blade sharpened on one side.

In Europe, this type of blade because of the difficulty of restoring sharpness on double-sided sharpeners not widespread. For this reason, the branches and subsidiaries of the Japanese and Chinese manufacturers in Europe produce zirconium table knives with a wedge-shaped cut, pointed symmetrically on both sides.

A blade ground in this way has the following advantages over a one-sided one:

- it is equally convenient to use "right-handed" and "left-handed" people;

- double-edged blade wears out more slowly;

- double-sided blade with a loss of sharpness is much easier to sharpen on a diamond disc or on a “nulevka” diamond sandpaper.

Considering the special hardness of the blade made of zirconium, it can be sharpened with a diamond tool in one of the following ways:

- on a special sharpener;

- on the diamond wheel;

- in the workshop on professional equipment.

According to experts, taking into account the price-quality ratio, the following Japan-made sharpeners for dressing zirconia blades are most common:

- Kyocera DS-20 mechanical sharpener (Japan);

- Kyocera DS-50 electric sharpener (Japan, on AA batteries);

- Kasumi 33001 sharpener (Japan, 2 compartments for zirconium and ordinary steel knives);

- electric machine for the gradual sharpening of the blade Chef's Choice 316 (China, but under license from Japan);

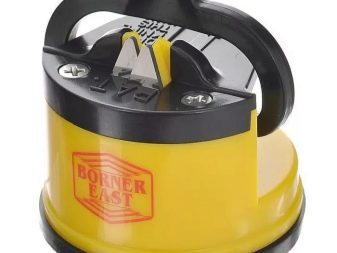

- TM Börner (Germany under the license of Japan, double-sided bar for quick sharpening double-sided blade).

Important! When using these devices, a high quality of blade sharpening is guaranteed regardless of the skills of the person who corrects the cut.

What is better to use?

To restore the sharpness of the zirconium blade at home, you can use a corundum sharpening bar, a mechanical sharpener, diamond skin and diamond paste. Using an electric-powered sharpener (mains or battery-powered) by a “Krivoruk” inexperienced craftsman can permanently spoil the shape of the blade. Properly sharpened edge of the blade when viewed in reflected light at a slight angle (up to 15 °) should be matte without shiny scratches, streaks and bright pointsek

No need to try to sharpen one-sided cermet cut from both sides. After such a “recovery” a very expensive blade will most likely have to be thrown away.

When sharpening a metal-ceramic kitchen blade made of zirconium with a single-blade blade, first sharpen the side that protrudes until a uniform barb is formed along the length of the cutting edge along the entire length. Then the blade is turned on the reverse and grind the burrs before leveling the surface. With double-sided sharpening, the blade is sharpened on one side until the burrs appear, then the knife is turned over and the point is absolutely the same.

To obtain a velvet surface at the end of processing using a diamond skin of zero size.

To sharpen a zirconium kitchen dagger on a diamond wheel, you must first purchase two diamond-coated circles, namely:

- with a grain of 80 microns for coarse processing;

- with a grain of 40 microns for final grinding.

To sharpen the ceramic blade you need at low speeds of the diamond wheel, constantly moving the knife along the grinding wheel with smooth circular movements, gradually reducing the pressure when approaching the blade edge. To sharpen the back side of the blade you need to flip and repeat processing.

To maintain the sharpness of the blade in the process of grinding a ceramic blade, be sure to maintain a factory sharpening angle.

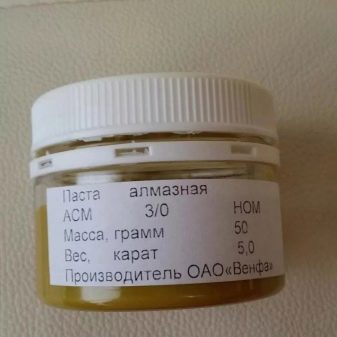

The most time-consuming method is to sharpen a metal-ceramic knife with a diamond paste by hand. To do this, you need to additionally purchase a wide leather belt or a wooden bar made of oak (beech).One end of the belt is securely fastened to the wall or to the surface of the table with a hook or screw. Diamond paste evenly smear on the surface of the leather belt and pull it with his left hand. The knife is taken in the right hand and with a small effort moves the blade back and forth through the belt by slightly pressing it to the surface.

After each pass, the blade is turned over. In the process, you must follow so that the blade is strictly parallel to the surface of the belt. If this condition is not met, you can spoil the shape of the thin edge of the blade and permanently spoil the kitchen cutter. In the process of work you need to be extremely careful not to cut your hands.

Sharpeners

The zirconium blade of the knife is resistant to high temperatures, much stronger than corundum and is inferior in hardness only to diamond. With intensive use in the kitchen in canteens, cafes, restaurants, even with strict observance of the rules of use and with careful handling, the razor-sharp knife blade loses its properties, it should be sharpened. Restore sharpness at home is easiest with a special device - sharpeners. The advantages of using this device are as follows:

- adequate price sharpeners licensed production;

- restoration of the correct angle of sharpening of an edge;

- guarantee of sharpness and safety of use;

- Sharpeners do not require special skills or knowledge.

Professionals, on the basis of their own experience, use lansky, Fiskars, and Victorinox bars and sharpeners to straighten the blades of zirconia knives.

Cheap roller sharpeners with pockets and corundum inserts (made in China) are strictly not recommended for sharpening metal-ceramic knives. The rollers leave deep scratches and chips on the blade surface. After processing a metal-ceramic knife blade that has lost its sharpness with such a “Chinese sharpening”, it most often deteriorates irrevocably, an expensive knife has to be thrown away and bought a new one.

Musat

Sharpening the blade of a knife from zirconium can, using musat - is a rod made of diamond and corundum chips with microcrystals of titanium and magnetized finely dispersed cobalt. The magnetized grinding tool attracts sawdust from the surface of the blade during sharpening. As a result, the sharp edge of the sharpened cut turns out perfectly smooth without burrs and minor scratches.

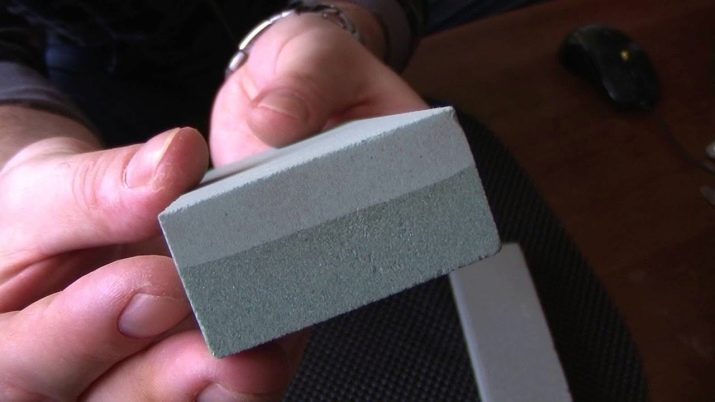

Bar

This is the most difficult method of restoring the sharpness of a zirconia blade. Sharpening the blades with this method requires a great deal of experience and jewelry skill from the master. During operation, the blade should be moved parallel to the surface of the sharpener with slight pressure at an angle of no more than 3–5 °. In order not to spoil the shape of the blade, as the bar approaches the edge, the pressure on the knife must be relaxed. Before starting work, the bar should be moistened with soapy water. It is not recommended to apply oil for the following reasons:

- an oiled knife begins to slide over the surface of the bar, this moment increases the processing time of the kitchen cutter;

- the grease from the blade can get onto the handle, which increases the risk of injury when sharpening as a result of the hand sliding off the handle onto the blade.

Important! The pressure on the blade should be uniform and not very strong. The movements are performed only in one direction from the handle to the tip 5–6 times with one (with one-sided grinding) or from each side (if grinding is two-sided).

General recommendations

It is recommended to cover the linoleum surface in the kitchen near the tabletop, on which a knife with a zirconium blade is used, with a rubber mat or piece of cavolina. Such a precautionary measure will save from destruction a rather expensive and fragile blade if accidentally dropped on the floor.When restoring the sharpness of the zirconium blade manually with diamond powder or wooden block and “zero” diamond sandpaper, do not press the knife blade against the working surface of the improvised sharpener with excessive force.

Instead of the expected acceleration of the blade sharpening process, the opposite effect is often obtained - the cutting surface of the blade is covered with coarse scratches, for smoothing which requires subsequent grinding and polishing for a long time. When used for sharpening the edges of the blade of the machine with an electric drive and diamond discs can not keep the knife in one place. Otherwise, there are deep longitudinal grooves or teeth and shells on the cutting edge of the blade. This error is almost impossible to fix, you have to buy a new knife.

To learn how to sharpen a ceramic knife, see the video below.